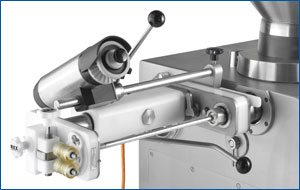

REX RKS 85 Calibration System

1 Р.

0.01$

0.01€

Select industry:

Meat industry

Condition:

New

REX calibration system from REX is a universal solution for the accurate calibration of all types of artificial and natural sausage casings, and due to its flexibility, can be integrated into any technological process. The concept of the system was developed in accordance with the needs of manufacturing enterprises of various capacities. When calibrating the sheath, the most important factor is achieving maximum accuracy in length and weight, which is the basis of economical production. The simplest transition from a natural shell to an artificial one and vice versa is also the basis of an effective and universal application. After the filling and twisting processes are completed, the sausages are transferred directly to both conveyor belts of the RKS calibration system. This feature optimizes the process of twisting the shell and, thus, minimizes the amount of marriage due to rupture of the shell. Conveyor belts are height-adjustable and, thanks to this, are easily adjustable for all calibers of sausage casing. The RKS sausage casings are calibrated to the desired diameter and provide the same weight and length of the sausage bar. This improves product quality in accordance with the desired quality criteria.

Comments

0

For publishing comment, you must to register or log in.

Similar ads